Fertilizer Mixer Machine Manufacturer

We offer a range of advanced fertilizer mixer machines designed to meet the needs of fertilizer manufacturers. Our mixers are essential for blending various raw materials so that they are the same throughout. This process creates high-quality compound and organic fertilizers. These machines make sure that the nutrients in the soil are balanced, which helps the plants grow better. Our machines are used by farmers of all sizes. They produce high-quality results, use energy efficiently, and are environmentally friendly. This meets the growing global demand for effective fertilizers.

Fertilizer Mixer Machine Definition

A fertilizer mixer is a machine that mixes different types of powdered or granular fertilizers. These machines are essential for making fertilizer. They mix formula feed, concentrated feed, additive premix, and organic and compound fertilizer raw materials.

Types of Fertilizer Mixer Machine

The mixing drum can handle a large volume of fertilizers, and the drum’s rotation mixes the materials thoroughly. The machine’s design makes sure the fertilizers are mixed evenly, creating a consistent mixture that can be used for various crops and soil types. The horizontal mixer can handle different types of fertilizers, including dry and wet fertilizers. It can mix them in the right amounts to meet the specific nutrient needs of different crops.

This is a machine that can mix different types of fertilizers. It is a versatile and efficient machine that can be used in many different types of agricultural settings. It can mix different types of fertilizers together, which is good for farmers because it saves money and is easier than using different fertilizers for each crop. The BB fertilizer mixer is designed with a high level of precision. This allows farmers to create customized blends with specific nutrient ratios. These ratios can help farmers get the most out of their crops.

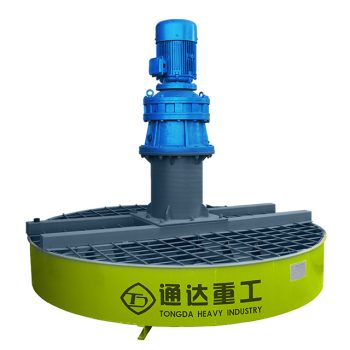

A disc mixer, also called a disc pan mixer or a vertical mixer, is a type of fertilizer mixer machine. It is used to mix different types of fertilizers, chemicals, or other materials so that they are the same. Secondly, it has a large circular mixing pan or disc that rotates on a vertical axis and is powered by a motor. The disc also has blades that mix the materials inside the pan, creating a tumbling motion that mixes them thoroughly.

This machine is often used to mix organic fertilizers. It is similar to a double shaft horizontal mixer. It has a large mixing shaft with blades that rotate around it. This creates a tumbling motion that mixes the materials inside the mixing chamber. The mixing blades lift and mix the materials, blending them thoroughly and evenly. However, a single-shaft mixer has only one mixing shaft, unlike a double-shaft horizontal mixer.

This is a machine that mixes fertilizer. It is used a lot to make compound fertilizers. It has two horizontal mixing shafts with blades that rotate around them. This creates a tumbling motion that mixes the materials inside the mixing chamber. The mixing blades are specially designed to lift and tumble the materials, creating a thorough and uniform blend.

Production Process

The mixing process is a critical step in fertilizer production, ensuring uniform nutrient distribution. The process typically includes:

- Material Preparation: Raw materials are crushed to a fine powder or prepared as granules.

- Batching: Materials are accurately measured using automated batching systems to achieve desired nutrient ratios.

- Mixing: Materials are fed into the mixer, where blades or paddles rotate to blend them evenly in a short time.

- Discharge: The uniformly blended material is discharged for further processing, such as granulation or packaging.

Fertilizer Mixer Machine Cost

The cost of our fertilizer mixer machines varies depending on the type, capacity, and customization level:

| Machine Type | Capacity (t/h) | Cost Range | Example Costs |

|---|---|---|---|

| Disc Mixer | 0.02-6 | $2,000-$8,000 | $2,000 for a 0.02 t/h model |

| Horizontal Mixer | 1-10 | $10,000-$50,000 | $30,000 for a 5 t/h model |

| Ribbon Blender | 1-30 | $20,000-$100,000 | $50,000 for a 10 t/h model |

| Vertical Mixer | 1-10 | $10,000-$50,000 | $35,000 for a 6 t/h model |

| Paddle Mixer | 1-10 | $10,000-$50,000 | $40,000 for a 8 t/h model |

Benefits of Fertilizer Mixer Machine

Improved Product Quality

Uniform granules ensure consistent nutrient delivery and better plant absorption.

Increased Efficiency

Streamlined processes reduce labor and time requirements.

Cost Savings

Energy-efficient designs and minimal waste reduce operational costs.

Environmental Sustainability

Recycling waste into fertilizers reduces landfill use and pollution.

Market Competitiveness

Meets the growing demand for high-quality, eco-friendly fertilizers.

Applications of Fertilizer Mixer Machine

Organic Fertilizer Production

Processes animal manure, agricultural waste, and industrial byproducts into organic fertilizer pellets.

Compound Fertilizer Production

Produces NPK, DAP, MAP, and other compound fertilizers for balanced crop nutrition.

Mineral Fertilizer Production

Granulates limestone, gypsum, and biochar for soil amendment.

Sustainable Agriculture

Supports eco-friendly farming by recycling waste into nutrient-rich fertilizers.

Landscaping and Gardening

Produces fertilizers for turf, ornamental plants, and home gardens.

Why Choose Us as Fertilizer Mixer Machine Supplier

Expertise

Our team of skilled engineers and technicians brings decades of experience in fertilizer production technology, ensuring reliable and efficient solutions.

Customization

We design fertilizer machines to meet your specific requirements, optimizing performance and cost-effectiveness.

Quality

We use premium materials and components, adhering to international quality standards.

Global Reach

We have successfully delivered solutions to clients across the globe, building trust and long-term partnerships.

Contact Us

Ready to elevate your fertilizer production? Contact us today to discuss your custom solution.